How to Make Wine: Essential Tips for Aspiring Winemakers

Imagine, if you will, a sun-drenched vineyard. Rows of emerald vines stretch towards the horizon, leaves rustling in the warm breeze. Plump grapes, jewels ripened by the summer sun, hang heavy on their canes. It’s a timeless tableau, one painted centuries ago and repeated across the globe, a silent promise of something intoxicating and profound. In that promise lies the essence of winemaking, a journey that transcends mere fermentation, an alchemy that transforms liquid sunshine into a symphony of senses and soul.

Learn How To Make Wine

For wine is not just a beverage; it’s a narrative woven in time. It whispers of ancient rituals, where terracotta amphorae cradled the first vintages, and of gods, like Dionysus, who danced through olive groves with grapes staining his lips. It echoes with the clatter of medieval barrels in stone cellars and the clinking of glasses raised in raucous taverns. Each sip carries the ghosts of laughter and tears, whispered secrets and boisterous celebrations, a testament to humanity’s enduring love affair with the vine.

But wine is also a poem penned by nature, a sonnet of terroir translated into taste. The caress of the Mediterranean sun, the crisp bite of mountain air, the mineral whispers of limestone soil – each nuance whispers its story in the glass. Each grape, a tiny sun-soaked prism, concentrates the essence of its place, its song echoed in the wine’s vibrant color, its lingering aroma, its delicate dance on the tongue.

And then, there’s the human touch, the artistry that guides the grape from sun-kissed fruit to liquid poetry. The winemaker, an alchemist of sorts, orchestrates the transformation, coaxing flavors from the shadows, shaping tannins like a sculptor, nurturing the delicate dance of yeast and sugar. Their passion is evident in every step, from the careful selection of grapes to the meticulous monitoring of fermentation, a constant dialogue between instinct and knowledge.

So, when you raise your glass, let it be more than just a quencher of thirst. Let it be a toast to time, to the sun and soil that birthed it, to the hands that nurtured it, and to the spirit that dared to capture the essence of a season in a single, glorious sip. This is the invitation of winemaking – to embark on a journey beyond the juice, to discover the symphony of sunlight and soul that sings within every glass.

Are you ready to raise your own toast? Then delve into the world of winemaking, its secrets waiting to be unlocked. With this guide as your compass, you too can become a part of this ancient narrative, crafting your own liquid sunbeam, your own ode to the vine. The journey awaits, brimming with the promise of discovery, delight, and the intoxicating magic of a drop of time captured in a glass.

A Brief History of Winemaking

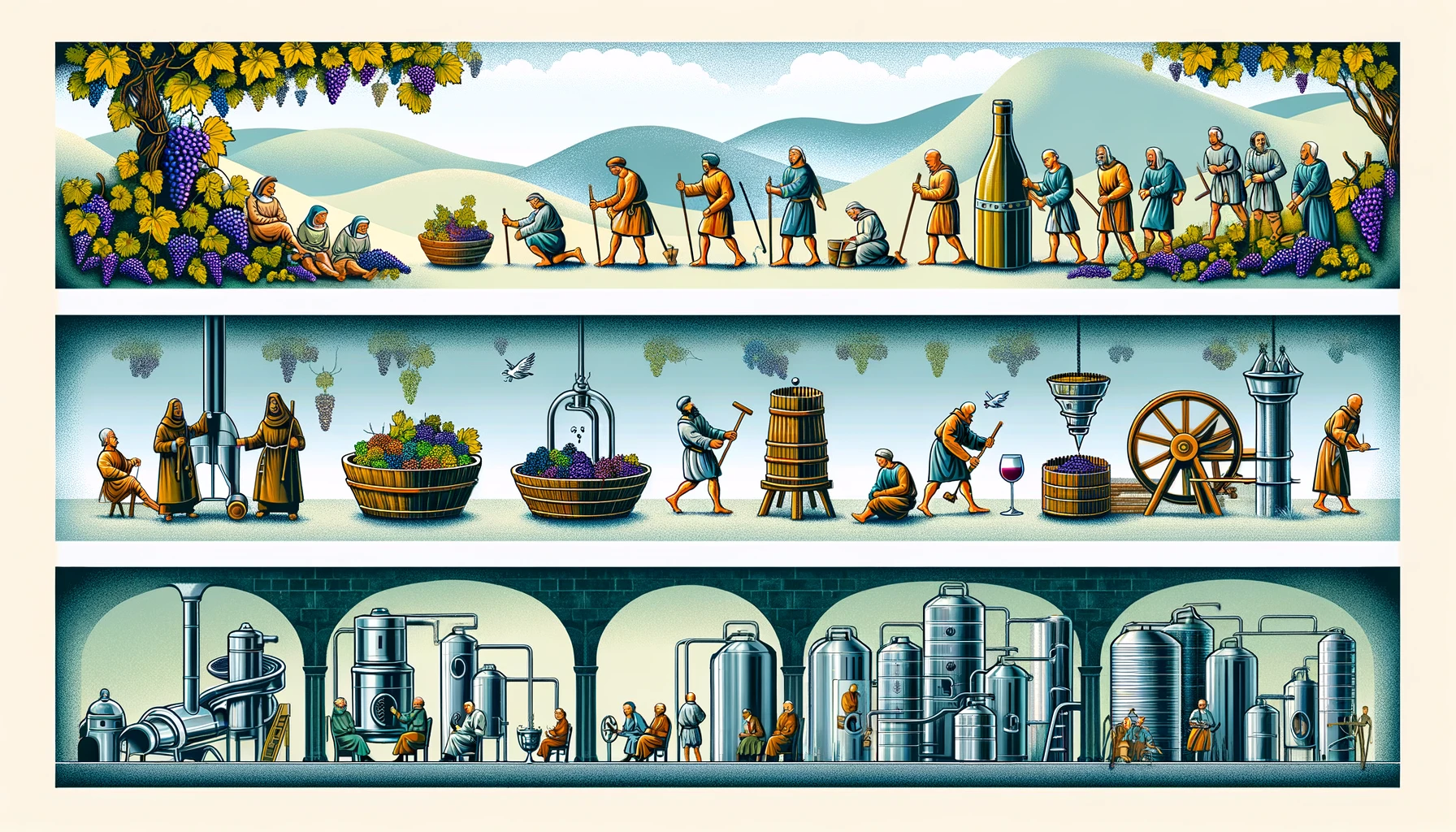

Let us toast, not just to the liquid sunshine before us, but to the tapestry of time woven into its very essence. Our journey begins not in modern vineyards, but in the cradle of civilization, the ancient Near East, where whispers of fermented grape juice date back over 8,000 years. There, amidst the sands of millennia, lies the birth of winemaking, a testament to humankind’s enduring fascination with the intoxicating and symbolic powers of the vine.

In the vibrant tapestry of history, wine’s threads intertwine with religion, rituals, and celebrations. Egyptians offered it to their gods, while Greeks raised amphorae to Dionysus, the boisterous god of wine and revelry. Roman patricians savored aged vintages like liquid gold, symbols of power and prestige. Throughout the ages, wine has flowed through triumphs and tragedies, marking milestones and igniting laughter in taverns and palaces alike.

But its significance transcends mere intoxication. Wine embodies connection, the shared joy of a well-chosen bottle savored amongst loved ones. It represents the delicate balance between nature and humankind, a dance between sun-drenched grapes and the skilled hands that guide their transformation. Each sip whispers of ancestors who tread barefoot on skins in ancient valleys, of monks tending sun-kissed vines on monastery slopes, and of generations gathered around warm hearths, sharing stories and dreams over brimming goblets.

So, when you raise your glass, remember the echoes of time it holds. In its ruby depths, taste the wisdom of ancient Egyptians, the revelry of Roman feasts, and the quiet contentment of centuries past. Wine is not just a beverage; it’s a living narrative, a whispered history passed down through generations, and a testament to our enduring love affair with the vine. Raise your glass, then, not just to the present pleasure, but to the echoes of time, the symphony of sun and soil, and the magic woven into every drop.

Choosing the Right Grapes

The foundation of any great wine lies in its grapes. Selecting the perfect varietal is an art, influenced by a symphony of factors: climate, soil type, desired style, and personal preference. Let’s explore some key considerations:

Climate: Warm regions like California and Australia favor bold reds like Cabernet Sauvignon and Shiraz, while cooler climates like Burgundy in France cultivate elegant Pinot Noirs and Chardonnays.

Soil: Grapes thrive in well-drained soils rich in minerals, influencing their acidity, tannin levels, and overall complexity.

Style: Do you dream of a light and fruity rosé, a robust and spicy Syrah, or a crisp and refreshing Sauvignon Blanc? Each grape variety possesses unique characteristics that translate into distinct styles.

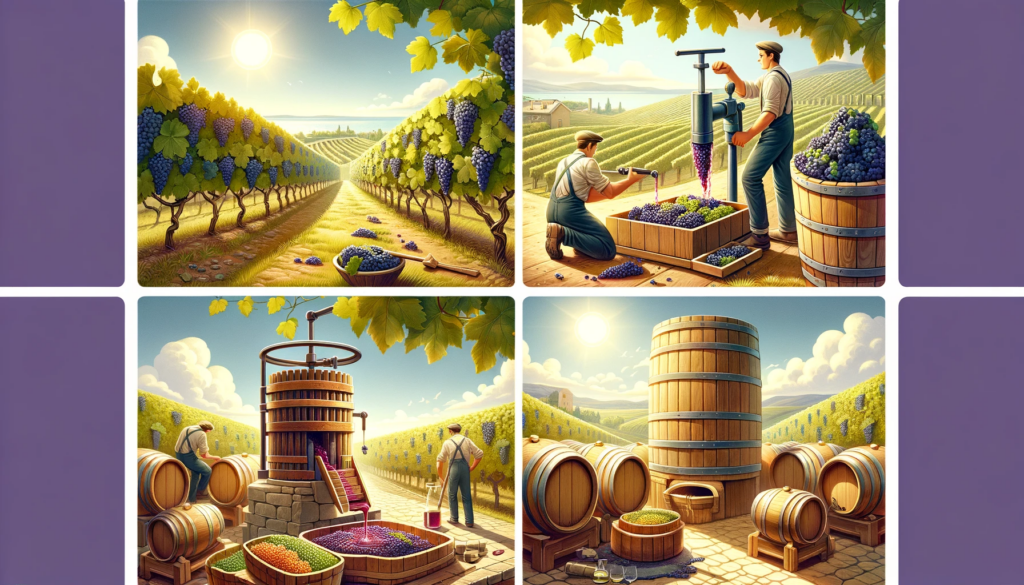

A Bounty from the Vine: Harvesting Grapes

When the grapes reach peak ripeness, their sugars and flavors sing their loudest. This is harvest time, a period of intense activity in the vineyard. Timing is crucial: underripe grapes lack sweetness, while overripe ones can become mushy and prone to rot. Skilled viticulturists meticulously assess grape maturity through visual cues, sugar content measurements, and even taste.

Crushing and Destemming: Releasing the Essence

The air hangs heavy with anticipation as plump, sun-kissed grapes arrive at the winery. Their journey from vine to vessel is just beginning, and the first crucial step in their metamorphosis is the release of their hidden essence. This is the realm of crushing and destemming, a dance between tradition and technology where the grape’s potential transforms from potential to possibility.

For centuries, the act of crushing was a ballet of human feet, a rhythmic stomping on skins that coaxed forth the precious juice. In regions like Portugal’s Douro Valley, this ancient art lives on, skilled men and women treading barefoot amidst the bounty, their movements as synchronized as the beat of a drum. Each step is a caress, a gentle pressure that liberates the vibrant liquid without bruising the flesh, ensuring a pure and delicate expression of the fruit.

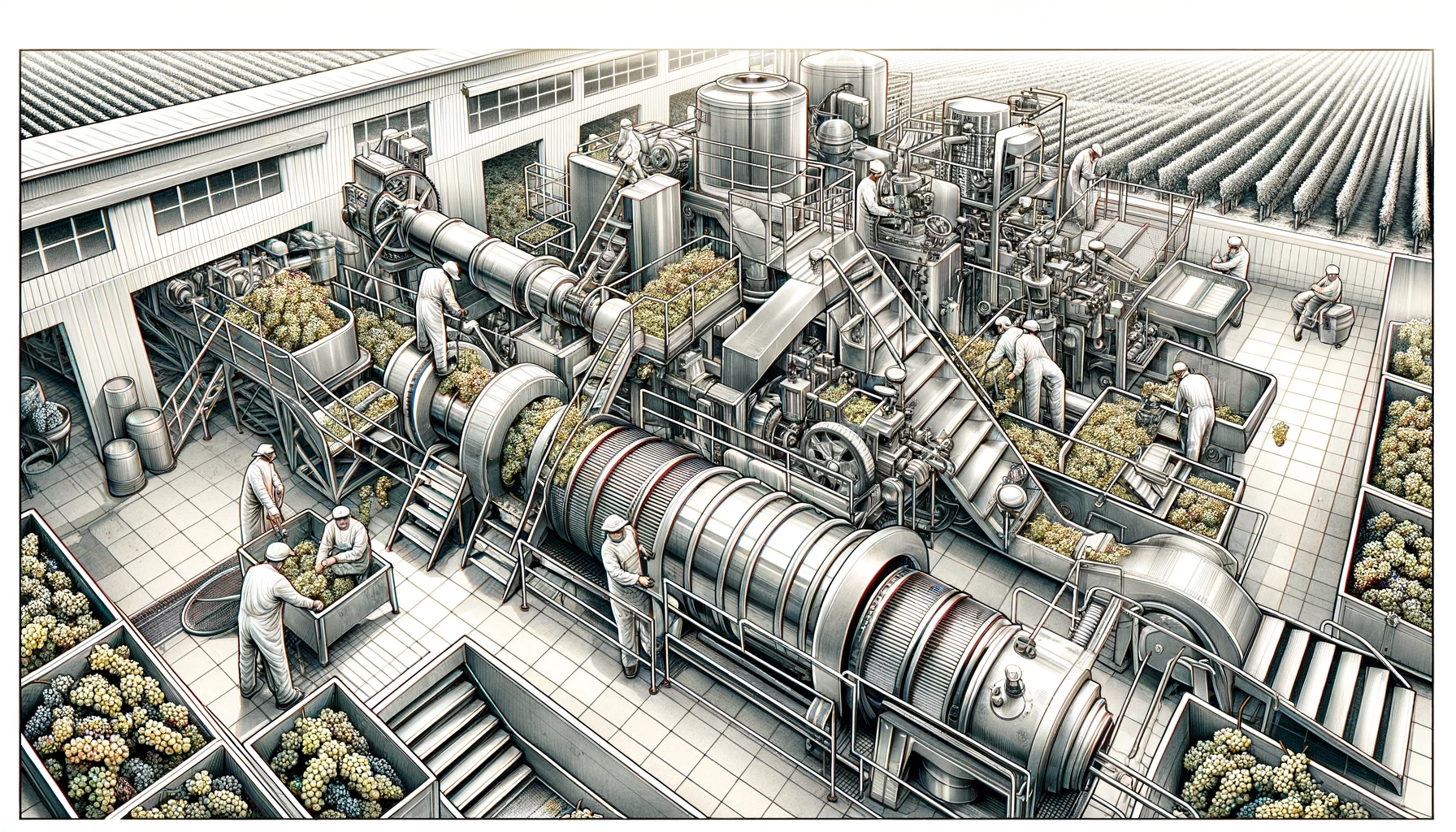

But time, ever the innovator, has also given rise to technological marvels. Modern crushers, be they gentle rollers or sleek spirals, handle the task with meticulous efficiency. Stainless steel teeth, calibrated to just the right bite, pierce the skins, releasing the nectar within while leaving the seeds unscathed. These mechanical dancers orchestrate a ballet of their own, a symphony of whirring gears and cascading rivers of juice that speaks of progress and precision.

Yet, regardless of the method, the essence of this stage remains the same: a liberation. The skins, once cradles of sun-drenched sweetness, now surrender their treasure, a vibrant cascade of ruby red or golden green, depending on the grape’s persuasion. With each crush, each roll, each gentle press, the wine’s personality begins to emerge, whispering promises of its eventual complexity and depth.

But amidst this symphony of juice release, another crucial step unfolds: destemming. The stems, once sturdy anchors for the grapes, now hold the potential to introduce unwanted flavors. Their woody character, if left unchecked, can impart harshness and astringency, a discordant note in the nascent wine’s melody. So, with deft hands or automated precision, the stems are separated, whisked away like discarded notes, leaving only the purest essence of the grape to continue its journey.

Crushing and destemming, then, are not merely mechanical processes; they are the gateway to the wine’s soul. They are the first brushstrokes on the canvas, the initial notes in the score. Whether guided by time-honored tradition or modern ingenuity, these steps mark the turning point, the moment when the potential of the grape transforms into the promise of a future vintage. Each gentle crush, each rhythmic stomp, each whisper of destemming carries the weight of history, the melody of terroir, and the anticipation of a final symphony to be poured, savored, and celebrated.

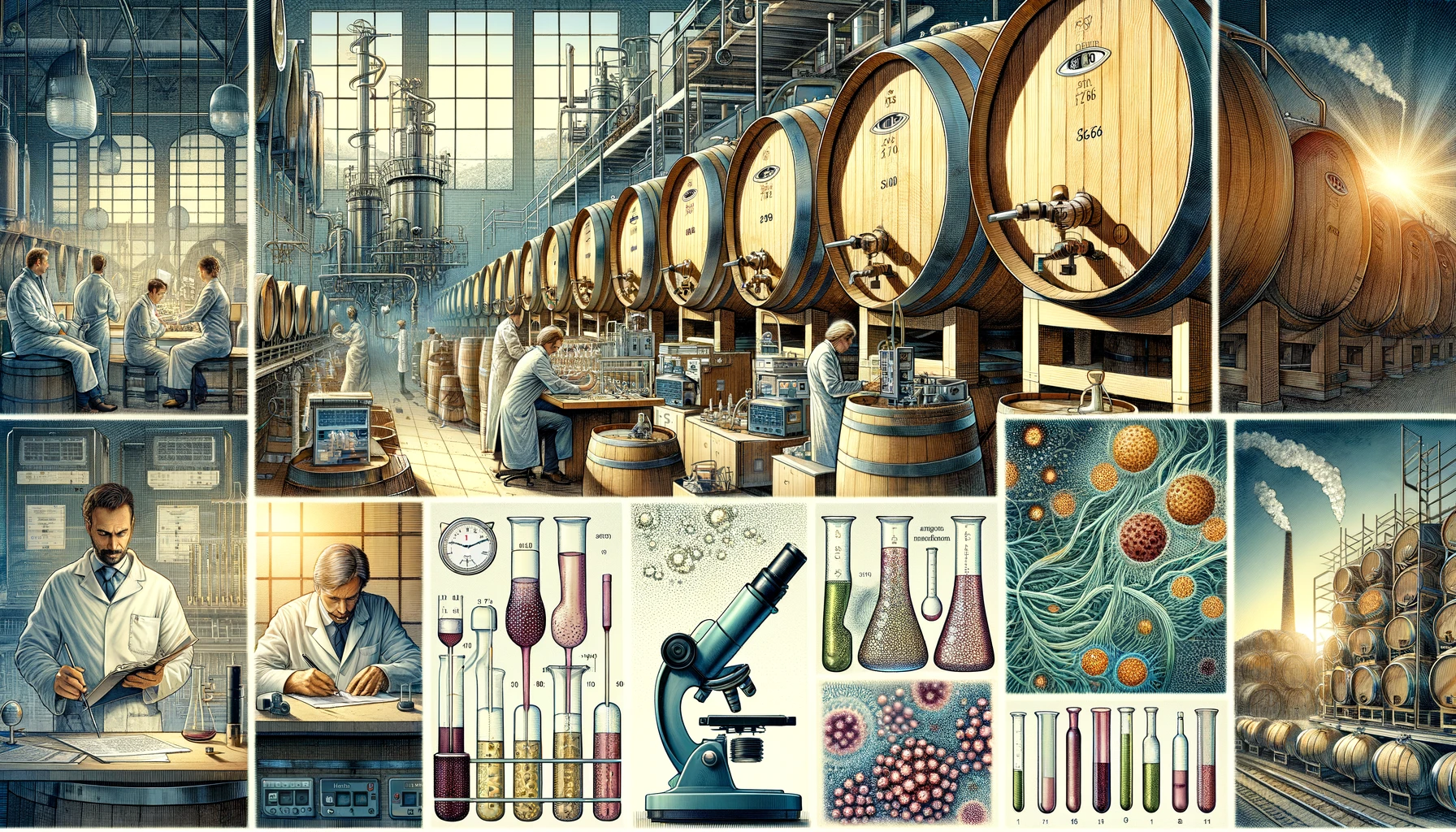

The Magic of Fermentation: Where Sugar Becomes Wine

Inside the hushed womb of the fermentation tank, sunlight whispers from beyond. Not in the form of golden rays, but as the sweet promise of ripe grapes, transformed into the cloudy nectar known as “must.” Here, beneath the watchful gaze of the winemaker, nature and science perform their most enchanting duet: the magic of fermentation.

Tiny, invisible ballerinas take center stage – yeast, nature’s alchemists in miniature. Driven by an insatiable hunger for the sugars trapped within the must, they pirouette and shimmy, their tireless choreography unlocking the true essence of the grapes. With each effervescent twirl, they convert sugar into alcohol, a chemical sleight of hand that breathes life into the nascent wine. The air hums with their industrious labor, a whispered symphony of transformation punctuated by the gentle hiss of escaping carbon dioxide.

But this dance is not without its intricacies. The choice of yeast strain becomes the conductor, guiding the wine’s final character. Wild yeasts, clinging tenaciously to the grape skins, lend a touch of rustic earthiness and unpredictability. Cultured strains, meticulously selected for their specific profiles, offer greater control, coaxing forth fruity notes, enhancing tannins, or influencing the wine’s body. In the winemaker’s hands lies the delicate decision: to embrace the wild charm of native yeasts or orchestrate the symphony with cultured precision.

As days turn into nights, the dance intensifies. The must bubbles and groans, the surface alight with a frothy cap of yeast. Temperatures rise and fall, monitored with hawk-like vigilance, for they orchestrate the tempo of the transformation. Too swift, and the wine loses its complexity; too slow, and it risks stagnation. The air thickens with the heady aroma of fermentation, a pungent bouquet of fermenting fruit, yeasty esters, and the nascent spirit that will soon become wine.

Through all this, the winemaker remains a watchful guardian, a translator of nature’s whispers. He tastes, samples, adjusts, nudging the must along its trajectory with gentle interventions. It is a dance of intuition and experience, a collaborative effort between nature’s microscopic ballerinas and the human hand guiding their steps.

And finally, when the music subsides and the bubbles settle, the transformation is complete. The must has transcended its humble origins, evolving into a young wine, its character shaped by the sun-drenched grapes, the tireless yeast, and the subtle artistry of the winemaker. Now, it embarks on its next journey, aging and maturing, its flavors deepening and its complexities unfolding like a story whispered in a glass.

A Dance with Nature

Inside the fermentation tank, a silent conversation unfolds. It’s a waltz between the winemaker and the unseen forces of nature, a delicate dance played out in whispers of carbon dioxide, the symphony of bubbling must, and the subtle shift in aroma with each passing day. Every step in this intricate interplay demands constant attention, for the fate of the future wine hangs in the balance.

Temperature, the unseen conductor, orchestrates the tempo of the dance. Too warm, and the yeast become frenzied, their rapid fermentation producing harsh alcohols and robbing the wine of its nuanced potential. Too cold, and the melody slows to a crawl, risking sluggish transformation and unwanted bacterial growth. The winemaker, armed with thermometers and years of experience, becomes a thermostatic whisperer, coaxing the yeast to express their best at the ideal tempo.

But temperature is only the first partner in this waltz. Sugar levels, the currency of fermentation, are meticulously tracked. Regular hydrometer readings measure the must’s sweetness, revealing the pace at which the yeast feast and alcohol accumulates. High levels signal potential imbalances, while depleting sugars can leave the wine flat and uninspired. Like a financial wizard, the winemaker guides the flow of sugar, adding nutrients if needed, to ensure a balanced and harmonious transformation.

Acidity, nature’s sharp counterpoint to the alcohol’s warmth, is another crucial element. Tartaric and malic acids add freshness and structure to the wine, but their levels require vigilance. Frequent pH readings track the acidity’s dance, and if it threatens to overshadow the harmony, the winemaker may employ techniques like malolactic conversion, a secondary fermentation that softens the edges and rounds out the character.

Finally, the waltz reaches its crescendo with the constant hiss of carbon dioxide, the effervescent punctuation of the yeast’s tireless work. Its release is monitored and sometimes gently encouraged, ensuring the tank doesn’t burst under the pressure of its own transformation. It’s a reminder of the invisible forces at play, a whispered dialogue between the winemaker and the microscopic beings shaping the destiny of the liquid within.

Monitoring the transformation is more than just checking numbers; it’s a conversation with the unseen, a delicate waltz where knowledge and intuition combine to guide the nascent wine towards its full potential. Each tasting, each measurement, is a brushstroke on the canvas of flavor, a note in the symphony of the future vintage. In this constant dialogue with nature, the winemaker becomes an artistic interpreter, translating the whispers of the unseen into a liquid poem waiting to be uncorked and savored.

Pressing the Essence: Separating Skin and Juice

Once the yeast have sung their final note, the fermented symphony within the tank falls silent. Yet, hidden within the slumbering sediment, a final whisper of the grape awaits. This is the domain of pressing, a gentle farewell embrace that squeezes the remaining essence from the spent skins and seeds, known as “pomace.”

Traditionally, the press was a place of creaking timber and groaning gears, where men wrestled with lever and screw, coaxing the last ruby tears from the crushed grapes. Today, technology lends a more efficient hand, hydraulics and pneumatic systems gently squeezing the pomace, mimicking the age-old embrace with steel and piston.

This press wine, as it’s called, is a different creature from the free-run juice that flowed freely in the early days. Rich in tannins, the astringent backbone of red wines, and boasting a deeper, earthier hue, it adds a layer of complexity to the final blend. Think of it as the chorus to the free-run’s lead vocal, adding depth and resonance to the finished symphony.

But pressing is not without its perils. Squeezing too harshly can unleash bitter notes and harsh tannins, overwhelming the harmony of the wine. The winemaker must tread a delicate path, coaxing the essence with measured pressure, leaving behind the unwanted bitterness in the lees.

With each press, another drop of lifeblood emerges, a final offering from the sun-kissed grapes. These are the whispers of the past, the echoes of sunshine and terroir, captured in a concentrated embrace. Blended with the free-run juice, they weave a richer tapestry of flavor, adding depth and dimension to the final wine.

So, let us raise a glass not just to the first flush of fermentation, but to the final press, a gentle farewell that squeezes the very essence from the grape, ensuring no note remains unsung in the symphony of the vine.

Secondary Fermentation: The Art of Malolactic Conversion

After the first, boisterous fermentation subsides, a hush falls over the tank. Yet, within this tranquil slumber, a subtle transformation can unfold, a hushed ballet of bacteria known as malolactic conversion. This second fermentation dances to a different tune, not the frenetic rhythm of sugar-gobbling yeast, but a slow, deliberate waltz that whispers of velvet on the tongue.

Malic acid, nature’s tart counterpoint to the wine’s warmth, can sometimes linger after the first act. Imagine it as a crisp green apple note, vibrant but potentially harsh. Malolactic bacteria, the quiet heroes of this stage, enter the scene and work their magic. They gently nudge the malic acid, transforming it into its softer cousin, lactic acid. This metamorphosis is no mere technicality; it’s a brushstroke on the canvas of flavor, a whisper of richness that rounds out the wine’s edges and adds a touch of buttery smoothness.

But like any artistic decision, whether or not to invite malolactic conversion to the dance is a crucial one. Some wines, particularly lighter styles, benefit from the bright bite of malic acid. For them, malolactic’s softening touch might be unwanted, masking their vibrant personality. But for full-bodied reds, or wines seeking greater complexity, the velvet touch of lactic acid can be a welcome guest. It deepens the color, broadens the palate, and adds a subtle richness that lingers on the finish.

The winemaker, then, becomes a conductor, deciding whether to let the natural melody of malolactic conversion play out or keep the orchestra of tartness in control. Temperature, nutrients, and time become their tools, carefully nudging the bacteria into action or gently suppressing their song. It’s a delicate dance, demanding both knowledge and intuition, for the final character of the wine hangs in the balance.

So, when you savor a glass of wine, listen not just to the fruit-driven melodies of fermentation, but also to the hushed whispers of malolactic conversion. It’s a subtle grace note, a touch of velvet on the tongue, a testament to the quiet artistry that unfolds within the hushed chambers of the winery. Whether embraced or gently discouraged, malolactic fermentation plays its part in the symphony of the vine, whispering its own story of softness and complexity in every drop.

Aging with Grace: Time Reveals its Secrets

As the final whispers of fermentation fade, the young wine embarks on its most transformative journey yet – a passage through time, where patience paints its masterpiece. Within the hushed cellars, it slumbers in silent communion with its chosen vessel, be it the time-worn embrace of oak or the cool, gleaming embrace of stainless steel. Each sanctuary offers a unique dance with time, unlocking secrets the grape held close to its heart.

In the oak’s hallowed halls, tannins, nature’s whisper of astringency, soften and meld, weaving themselves into the tapestry of flavor. Hints of vanilla and spice, born from the sun-kissed wood, rise like wisps of smoke, adding depth and intrigue to the young wine’s palette. Time, the patient sculptor, polishes the rough edges, crafting a harmonious blend of fruit and oak, a symphony of complexity waiting to be savored.

But steel, too, has its story to tell. Its unwavering chill preserves the fruit’s vibrant song, capturing the grape’s youthful exuberance in a crystalline snapshot. Think of it as a spotlight trained on the varietal’s essence, showcasing its purity and unbridled zest. In this vessel, time plays a different song, a concerto of freshness and vibrancy, a celebration of the grape’s raw, unadulterated beauty.

Choosing the vessel, then, is an act of artistic creation. The winemaker, like a sculptor contemplating the raw marble, envisions the final masterpiece. For wines of power and longevity, oak’s gentle hand offers the perfect canvas, while for expressions of purity and immediacy, steel’s unwavering gaze becomes the ideal partner.

And just as every sculpture whispers the story of its creation, the length of the aging dance tells its own tale. A quick slumber in oak might lend a fleeting kiss of complexity, while years of patient rest can weave a tapestry of tannins and oak-kissed nuances. For lighter styles, stainless steel’s embrace might be just a short sojourn, preserving the fruit’s youthful exuberance.

So, when you lift a glass, remember the artistry of time. In every swirl, in every sip, taste the echoes of patient slumber, the whispers of oak and steel, the secrets the grape surrendered to time’s gentle touch. For a well-aged wine is not just a beverage; it’s a masterpiece sculpted by nature and time, a testament to the magic that unfolds in the hushed shadows of the cellar.

Racking for Clarity: Leaving the Sediment Behind

As the wine slumbers in its chosen vessel, time unfurls its invisible tapestry. But within the shadowed depths, a silent story unfolds – the settling of sediment, a gentle rain of grape skins, seeds, and yeast, the remnants of the transformation journey. Left unchecked, these motes of the past can cloud the wine’s future, casting a veil over its pristine beauty. This is where the art of racking steps in, a graceful dance of light and shadow, where clarity is meticulously separated from its slumbering counterpart.

Imagine, if you will, a ballet of gentle siphons, their elongated necks gliding through the hushed liquid, seeking the boundary between clarity and sediment. They whisper secrets to the winemaker, tales of tannin and lees, of the silent history settling below. With practiced hands, the winemaker guides the flow, coaxing the clear liquid away from its shadowy past, like a sculptor separating marble from the dust of creation.

Each racking is a poem of purification, a testament to the relentless pursuit of brilliance. For sediment, though natural, can introduce unwanted bitterness and harshness, discordant notes in the wine’s otherwise harmonious symphony. By gently separating the two, the winemaker crafts a canvas of purity, a stage where the grape’s true character can shine in all its unadulterated glory.

But racking is not a mere act of separation; it’s a conversation with time. Young wines might require more frequent “meetings,” as their sediment settles quickly, seeking its place at the bottom. Aged wines, however, hold their secrets closer, their sediment a patient storyteller whispering of years gone by. The frequency of the dance, then, becomes a delicate negotiation, a balancing act between preserving the wine’s youthful vibrancy and honoring the wisdom held within its slumbering past.

So, when you cheers, remember the quiet heroism of racking. In every drop, taste the echoes of separation, the dance of light and shadow, the relentless pursuit of clarity. For racking is not just a technical necessity; it’s a testament to the artistry of winemaking, a silent promise whispered into every bottle, ensuring that the grape’s story unfolds in all its luminous, unclouded beauty.

Bottling the Dream: From Grape to Glass

The journey unfolds like a sun-drenched tapestry, woven from fertile vines, tireless yeast, and the watchful eyes of the winemaker. Now, at its culmination, it reaches its final flourish – the moment when whispers of sunshine are captured in glass, becoming tangible dreams ready to be uncorked and savored. This is bottling, the stage where liquid poetry is encased in crystal, a poem waiting to be read with lips and fingers trailing across the cool glass.

Each bottle becomes a microcosm, a sun-kissed sphere cradling the essence of the vineyard. Carefully measured quantities, guided by a practiced hand, flow from tank to bottle, carrying with them the echoes of fermentation, the whispers of aging, and the tireless dedication of the winemaker. Corks, guardians of liquid dreams, are meticulously inserted, sealing the symphony of flavors within. Screw caps, sleek and modern, offer a whisper of efficiency, yet still hold tight the secrets the wine holds close.

But the transformation is not complete without a story. Labels, like poems etched in ink, unfold the narrative of the grape’s journey. Vintage, varietal, terroir – each detail whispers of sun-drenched slopes, the caress of the wind, and the hand that guided the grape from vine to glass. It’s a visual poem, an invitation to embark on a sensory journey before the first drop touches your tongue.

For in every bottle lies a dream – the winemaker’s vision materialized, the sun’s gift transformed into liquid poetry. It’s a testament to the intricate dance of nature and human expertise, a collaboration whispered in every swirl, every sip. The cork pops, the label unfolds, and suddenly, the sun-drenched tapestry woven over months unfolds on your palate, a symphony of light and flavor born from the earth and nurtured by passion.

So, hold a bottle aloft, a sun-kissed sphere cradling liquid dreams. Its weight is the story of its journey, its label a whispered invitation. With each sip, taste the sunshine, the earth, the tireless hands that guided it all the way. For in that moment, the dream that began in a sun-drenched vineyard finds its fulfillment in your glass, a symphony of time and nature waiting to be uncorked and savored.

Storing and Aging Bottled Wine: Preserving the Essence

Though the cork is popped and the label unveiled, the wine’s story doesn’t end at the lip of the glass. For within the hushed chambers of your cellar, or nestled gently on a dimly lit shelf, a whispered conversation with time continues, an evolution that paints its masterpiece in slow brushstrokes. Here, in the cool, dark quiet, the essence of the grape slumbers, awaiting the perfect moment to reveal its deepest secrets.

Temperature, the guardian of time’s melody, dictates the pace of this silent waltz. Imagine a hushed conservatory, bathed in perpetual twilight, where rays of heat dare not intrude. In this sanctuary, the wine slumbers, its molecules lulled to a gentle tempo, allowing the symphony of flavors to mature with graceful composure. Too warm, and the melody quickens, notes becoming discordant, the story rushed and incomplete. Too cold, and time slumbers in a frozen embrace, the story untold, its potential forever locked away.

Humidity, the whisperer of balance, plays its own crucial role. In the arid silence of a forgotten attic, or the damp whispers of an unloved basement, the wine’s delicate structure can crumble. Dry air parches the cork, inviting unwelcome invaders, while excessive moisture can cloud the story with unwanted mustiness. But within the gentle embrace of moderate humidity, the cork remains supple, the air a soft blanket protecting the liquid poem within.

For some wines, this hushed conversation with time unfolds over days, their youthful vibrancy waiting only to be savored. But for others, it’s a saga whispered over years, decades even. Imagine a library of dusty bottles, each holding a chapter in the story of the vine, their aromas deepening, their flavors evolving into symphonies of complexity. With each passing year, the tannins soften, the fruit acquires a patina of wisdom, and the whispers of oak weave themselves into the tapestry of flavor.

But like any conversation, knowing when to listen and when to intervene is key. Opening a bottle too soon is like interrupting a whispered tale, leaving the story untold. Yet, leaving it to slumber eternally risks missing the crescendo, the moment when the wine sings its fullest note. The winemaker’s whispers, the echoes of vintage and terroir, become your guiding stars, helping you navigate the delicate balance between youthful exuberance and aged complexity.

So, the next time you cradle a bottle in your hand, remember the hushed conversation it carries within. In its cool embrace, taste the whispers of time, the gentle touch of darkness, and the secrets patiently waiting to be unveiled. For when stored with care, a bottle of wine is not just a beverage; it’s a living story, an ongoing conversation with time, waiting for the perfect moment to reveal its soul, one sip at a time.

Serving and Tasting Wine: A Symphony of the Senses

The culmination of sun-kissed vines, tireless yeast, and the winemaker’s artistry arrives in a hushed ceremony – the opening of the bottle. Cork freed, its gentle pop a sigh of anticipation, the wine within awakens from its slumber, eager to tell its story through a symphony of the senses.

Light ignites the liquid poem. Swirl the crystal chalice, and watch as the sun’s embrace dances within – ruby depths swirling with garnet edges, or pale straw hues whispering of sunshine and citrus. Each turn paints a fleeting masterpiece, a prelude to the olfactory aria that awaits.

Nose poised above the rim, take a gentle breath, a whispered invitation. Close your eyes, and let the first act unfold. Fruit, ripe and luscious, bursts forth – berries, stone fruits, or tropical breezes painted by the varietal’s song. Oak, a seasoned actor, lends its notes of vanilla, spice, and toasty warmth, adding depth and intrigue to the aromatic performance.

The palate awaits its cue. Take a sip, small and measured, let the liquid poem play across your tongue. Fruit, bright and vibrant, makes its playful entrance, balanced by the acidity’s crisp counterpoint. Tannins, nature’s astringent whisper, add structure and complexity, building anticipation for the crescendo.

Swirl, sniff, sip, savor – a mantra whispered through generations. Repeat the performance, each act revealing a new nuance, a hidden emotion in the wine’s story. Earthiness murmurs of terroir, a touch of minerality adds intrigue, and the gentle warmth of alcohol becomes a supporting melody.

With each drop, the symphony builds. Notes blend and harmonize, weaving a tapestry of flavor that speaks of sun-drenched slopes, patient aging, and the winemaker’s guiding hand. The finish, a lingering echo on the palate, becomes the final bow, a whisper of satisfaction that lingers long after the glass is empty.

But remember, the conductor of this symphony is you. Temperature, a crucial tempo setter, unlocks the wine’s potential. Too cold, and the melody remains muted, its notes hidden in chilled silence. Too warm, and the performance overtakes you, its crescendo jarring and discordant. Find the ideal harmony, the temperature where the wine’s song unfolds with effortless grace.

So, raise your glass, a crystal stage for the liquid poem within. With each swirl, sniff, sip, and savor, become an immersive audience, lost in the symphony of the senses. For in that moment, you are not just drinking wine; you are experiencing a story, a journey from vine to glass, a testament to the art that whispers in every drop.

Wine Making Tips and Tricks: Wisdom from the Vineyard

As you embark on your winemaking adventure, remember these precious nuggets of wisdom:

Start small: Begin with a small batch of wine to practice your skills and gain confidence before scaling up.

Cleanliness is paramount: Sanitation is crucial throughout the process to prevent unwanted bacteria and spoilage.

Pay attention to detail: Every step, from grape selection to bottling, matters in the final outcome.

Don’t be afraid to experiment: Winemaking is an art, not a science. Explore different grape varieties, fermentation techniques, and aging methods to find your personal style.

Most importantly, have fun!: Winemaking is a rewarding journey filled with learning, experimentation, and shared enjoyment. Relax, enjoy the process, and celebrate your creations.

From Vine to Glass, a Tapestry Woven in Time

Winemaking is a tapestry woven in time, its threads spun from sunlight, water, and the meticulous hand of humankind. It’s a saga that stretches back millennia, from the clay amphorae of ancient Greece to the gleaming stainless steel tanks of modern wineries. In every bottle lies a story, a whispered echo of sun-drenched vineyards, the rhythm of crushing grapes, and the quiet hum of yeast working its magic.

For the winemaker, the journey begins in the vineyard. Each grape, a tiny jewel suspended in sunlight, holds the promise of something extraordinary. Careful hands select the ripest clusters, their senses attuned to the subtle nuances of sugar content and skin color. The harvest, a fleeting moment of frenetic energy, marks the transition from vine to vessel.

From the gentle crush of the grapes to the bubbling symphony of fermentation, each step in the winemaking process is a delicate dance with nature. Yeast, those microscopic alchemists, transform sugar into alcohol, unlocking the latent flavors and aromas locked within the grape. The air hangs heavy with the heady scent of fermenting juice, a promise of the liquid poetry to come.

As time weaves its magic, the young wine slumbers in oak barrels or stainless steel tanks. The wood whispers stories of the past, infusing the wine with hints of vanilla and spice. In the cool hush of the cellar, tannins soften, colors deepen, and the symphony of flavors reaches its crescendo.

Finally, the moment arrives. The cork pops, releasing a sigh of anticipation. The wine, now a polished jewel, dances in the glass, its color catching the light like a stained-glass window.

The first sip explodes on the palate, a kaleidoscope of fruit, acidity, and tannin. With each swirl, each breath, the story unfolds, revealing the terroir, the grape, the hand of the winemaker.

Wine is more than just a beverage; it’s a bridge between cultures, a catalyst for conversation, and a celebration of life’s fleeting moments. It’s a testament to the enduring power of human passion, a love letter to the land, and a whispered promise of joy in every bottle.

So, give a nod to the sun-kissed grapes, the tireless winemakers, and the shared pleasure of a bottle enjoyed with loved ones. Remember, with a little dedication and this guide as your compass, you too can unlock the magic of winemaking and transform ordinary grapes into something truly extraordinary.

As you embark on your own vinous adventure, may your journey be brimming with the rich tapestry of flavors, the warmth of camaraderie, and the quiet satisfaction of a craft well-honed. Let each sip be a reminder of the sun, the soil, and the story whispered in every glass.

Winemaking Fun Facts: Grape Expectations and Fermentation Feasts

1. Picking the Perfect Players: Imagine grapes as superheroes, each bringing special powers to the wine party. Reds like Cabernet Sauvignon, Merlot, and Pinot Noir are bold and tannic, building structure like sturdy knights. Whites like Chardonnay, Sauvignon Blanc, and Riesling are sassy and bright, adding zesty acidity like witty wizards. But the real magic happens when you choose grapes perfectly ripe, healthy, and ready to rock their specific styles!

2. Sugar Rush for Boozy Blastoff: Think of sugar as the rocket fuel for your wine. The more the grapes have, the higher the alcohol content after the yeast party (fermentation). We measure this fuel with fancy tools like Brix or Baume, making sure it’s just right for a balanced, flavorful, and not-too-heady final wine.

3. Yeast: The Funky Friends at the Fermentation Fiesta: Picture tiny, bubbly party animals munching on grape sugar and turning it into alcohol and burps (carbon dioxide). That’s yeast! We can invite wild ones already hanging out on the grapes, or bring cultured friends for a controlled party. Reds like it hot, fermenting at higher temperatures than whites, and the whole bash can last days or weeks, depending on the desired vibe.

4. Home Brew Hero: You Got This! Making your own wine isn’t just for fancy folks in chateaus. Grab some buckets, a sugar meter, and a thermometer, and you’re basically a fermentation DJ! Get fancy with siphoning tubes to transfer your bubbly brew, airlocks to keep the party private, and bottles and corks for the grand finale. Feeling fancy? Start with a winemaking kit – it’s like training wheels for your inner Bacchus!

5. Picking the Perfect Yeast Peeps: Choosing the right yeast is like hiring the perfect band for your fermentation fiesta. Each strain brings its own flavor and aroma magic. Some make big, burly red wines, while others whisper delicate notes in whites. Consider the temperature, alcohol tolerance, and desired style of your wine before inviting these funky friends to the party.

6. Aging with Grace: From Rough Diamond to Sparkling Gem: Imagine your wine as a rough diamond. Aging polishes it up, softening tannins, blending flavors, and adding complexity. It can chill in tanks, barrels (for toasty, vanilla vibes!), or even just hang out in bottles. The longer the party, the smoother and more sophisticated the wine becomes – think months for some, years for others, it all depends on the desired style!

7. Bottling Bonanza: Knowing When to Pop the Cork: Your wine is ready to graduate from the fermenting frenzy when the bubbles stop flowing, the sugar readings stabilize, and it turns crystal clear. Taste it before corking, like the final quality check before the big reveal. This is your moment of winemaking glory!

8. Malolactic Magic: From Sharp to Smooth: Think of malolactic fermentation (MLF) as a spa day for your wine. Friendly bacteria transform sharp malic acid into smooth lactic acid, like turning lemons into lemonade. It’s more common in reds and some whites (Chardonnay loves it!), making the wine softer, creamier, and more stable.

9. Sweet Tooth Tantalizers: Keeping Your Wine Just Right: Sweetness in wine is like the DJ controlling the bass. The more sugar left after fermentation, the sweeter the tune. Want a sweeter jam? Stop the party early or add some grapey goodness later. Just remember, stabilize your wine first to avoid accidental re-fermentation!

10. Wine Woes and Wise Fixes: Even the best parties have hiccups. Stuck fermentation? Yeast might need a nap or a nutrition boost. Oxidation? Minimize air exposure. Funky flavors? Check for wild yeast or bacteria crashers. Remember, a little troubleshooting can turn wine woes into winning moments!